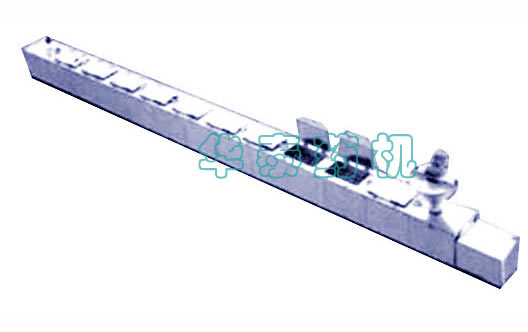

Product Name: Continuous Dynamic Reflux Extraction Unit

Purpose: This unit is brand-new dynamic extraction equipment used to lixiviate effective component in natural products (especially Chinese medical materials). Have been awarded the national patent, the unit is equipped with auxiliary facility such as condenser, meeting dissolvent recycle process requirement and etc.

Features: The unit is invented and designed based on years of experience according to production theory and discipline of modern natural products (especially Chinese medical materials).

The unit is connected by several individual lixiviate tank with special facility and external heating jacket, material flowing piping and fluid flowing piping (extend stoke in order to create maximum concentration difference). Extraction temperature shall be selected properly according to material characteristic. Heating medium is normally steam, or heat water, heat conducting oil (easily control at low temperature). According to Chinese medical material extraction theory, the optimum lixiviate temperature for normal medical material is 80¡æ,so as to prevent heat sensitive component destroyed, lixiviate amylum etc. in difficulty and reduce the difficulty of filtering as next step.

The unit is interacting reflux process: Feed fixed amount material through material inlet and inject controlled amount solvent through solvent inlet. Propelled by special device, lixiviated liquid and material form reverse continuous reflux lixiviate process. The prime forward outflow is extraction solvent in which effective component has been sufficiently lixiviated; the prime backward outflow is material slag almost without effective component. The material slag enters into squeezer or dissolvent recycle machine for treatment is economic and environmental-friendly. Whole unit is an enclosed system, apply to lixiviate of volatile organic dissolvent and water as solvent. It is clean and convenient because material feed and slag discharge are controlled automatically. Open the top cover could start cleaning.

Main Technique Parameter£º

| Para\Model Spec. |

ND-50 |

ND-100 |

ND-150 |

ND-200 |

ND-300 |

ND-400 |

ND-1000 |

| Capacity(L/h) |

125 |

250 |

275 |

500 |

625 |

750 |

2500 |

| Pressure in Jacket(MPa) |

<0.09 |

| Tank Pressure (MPa) |

Normal atmospheric pressure |

| Tank Temperature(¡æ) |

0¡«100¡æ |

| Power(KW) |

3¡«4 |

4¡«6 |

| Material Running Time(min) |

30¡«120 |

| Filtration Coefficient |

8¡«15 |

| Granularity of Material |

Around¦Õ5mm, decoction pieces or rough powder |

Outline Dimension(m)

L¡ÁW¡Áh |

15¡Á2¡Á3 |

15¡Á2¡Á3 |

15¡Á2¡Á3 |

15¡Á2¡Á3 |

16¡Á3¡Á3 |

16¡Á3¡Á3 |

17¡Á3¡Á3 |

|